2025 wasn't the year humanoid robots showed up in your home. It was quieter than that. Fewer flashy promises, more real systems actually working in the world, and clearer signals about which companies might actually pull this off.

Here's what stood out - not because it looked impressive on stage, but because it signals how humanoid robots will actually get built and deployed.

The Game-Changers (Tier 1)

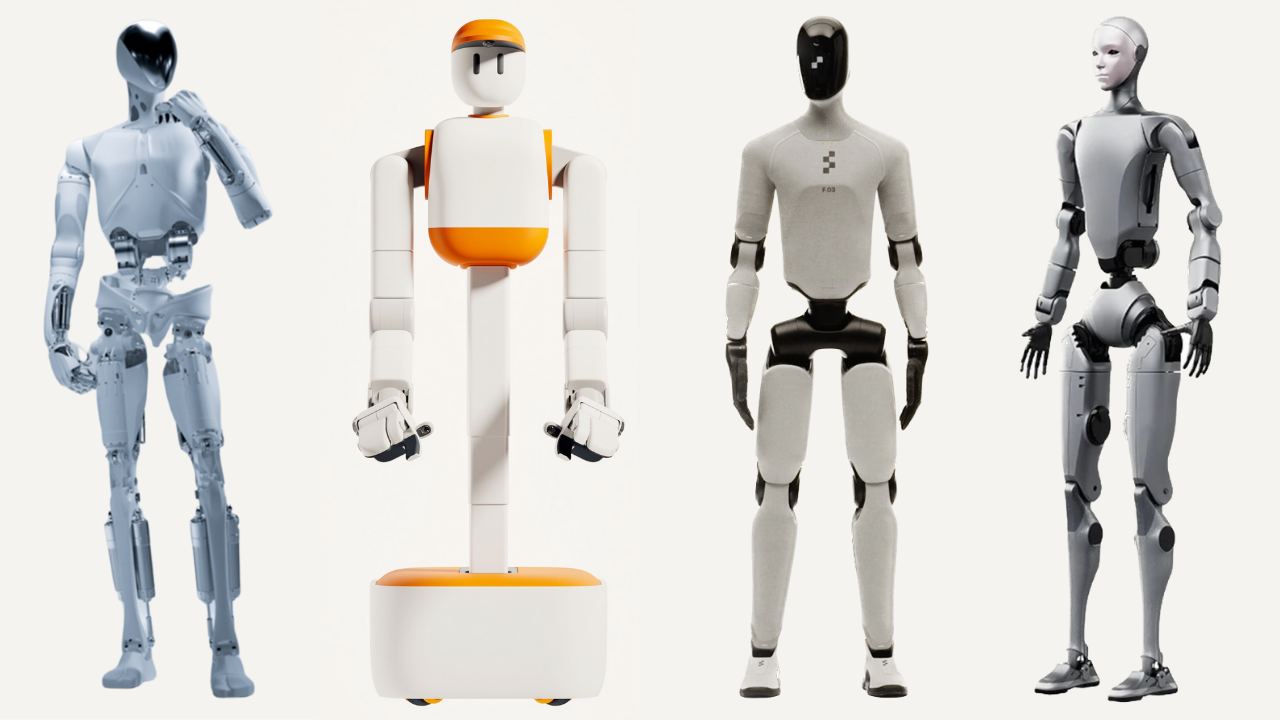

Figure 03 — Figure AI

Driver: Iteration velocity + generality

Figure AI (backed by talent from Tesla, Boston Dynamics, and OpenAI) keeps releasing new versions of their humanoid faster than anyone else. Figure 03, their 2025 iteration, doesn't do anything shocking, but it learns faster, manipulates objects better, and moves more smoothly. The real impact? Speed. By iterating constantly and testing in the real world, Figure is forcing competitors to move quicker or get left behind.

What to watch: whether Figure can turn this speed into large-scale deployments, not just impressive demos.

Kepler K2 "Bumblebee" — Kepler Robotics

Driver: Manufacturing and real-life deployments

This Chinese company did something unusual: they actually started mass-producing their humanoid robot in 2025. Most companies show prototypes. Kepler started building them in volume and putting them to work in real factories. That shift in thinking—treating humanoids as industrial machines that need to be reliable and manufacturable, not research projects—is rare and important. It suggests humanoids might succeed on factory floors first, before they ever come home.

What to watch: whether K2 deployments expand beyond tightly controlled environments into more flexible roles.

Memo — Sunday Robotics

Driver: Training methodology and economics

Sunday Robotics took a different bet. Instead of building the strongest humanoid, they focused on the hardest problem: teaching robots cheaply. Memo is designed to interact with humans constantly and safely gather training data. Most robots require expensive human control (someone basically puppeteering them) or risky real-world experiments. Memo sidesteps both by using their Skill Capture Glove. If this low-cost learning approach actually scales, it changes everything about how fast the industry can progress.

What to watch: whether this low-cost training approach can transfer to more physically capable humanoids.

The Ambitious Players (Tier 2)

H2 — Unitree Robotics

Driver: Cost accessibility

Unitree (known for affordable robot dogs and research bots) brought their humanoid to wider availability in 2025. The impact? Lower cost means more labs and startups can experiment without massive budgets. That indirectly accelerates innovation across the field.

What to watch: whether low cost comes at the expense of long-term capability growth.

Iron — Xpeng Robotics

Driver: Extreme anthropomorphism + automotive platform

Xpeng, the Chinese EV company (think Chinese Tesla), made headlines in 2025 with Iron, a humanoid that looks remarkably human—almost unnervingly so. Iron is noteworthy for combining lifelike human form with industrial know-how. Its car-derived production infrastructure could accelerate scaling and reliability faster than typical humanoid startups.

What to watch: whether XPeng leverages its automotive expertise to deliver volume-ready, versatile humanoids—or if Iron remains a high-tech showpiece.

The Emerging Players (Tier 3)

4NE-1 Gen 3 — Neura Robotics

Driver: Cognitive integration

Germany's Neura Robotics is pushing toward robots that don't just move well—they actually understand what's happening around them and can interact safely with people. This cognitive layer matters for humanoids to work in shared human spaces. The catch: they're betting on smarts over speed, and faster-moving US and Chinese companies might outpace them.

What to watch: whether Neura can keep pace with faster-moving US and Chinese competitors.

Industrial Variants — AgiBot

Driver: Industrial execution

Agibot's humanoids include the full-size A-Series, half-size X-Series, and task-optimised G-series. This Chinese company doesn't revolutionize anything. They just show discipline: they take humanoids from prototype to working in actual factories, reliably, on schedule. That execution matters more than you'd think. They have recently announced the rollout of their 5000th humanoid.

What to watch: whether AgiBot can broaden capabilities beyond narrowly defined tasks.

What This Really Tells Us

The biggest lesson from 2025 is this: the future belongs to whoever can make humanoids learn fast, deploy reliably, and cost less—not whoever makes them look most human on stage.

Some of these robots push the boundaries of what's possible. Others quietly make robots cheaper to train or easier to deploy. Together, they prove humanoid robots aren't science fiction anymore. They're systems that can actually scale.